- Self-Study Guided Program o Notes o Tests o Videos o Action Plan

Scientists have found a new method to improve the transportation of fluids like chocolates, lotions, sauces by tuning the viscosity and elasticity of fluids during materials processing in the food and personal care products industries.

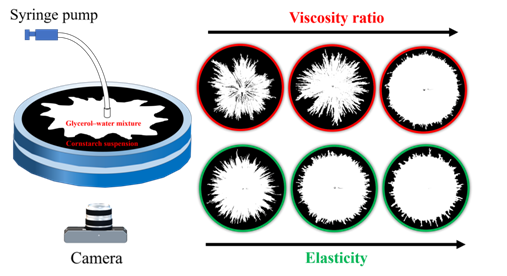

Usually the transport of fluids through pipelines involves displacement of a more viscous fluid by a less viscous one. This creates instabilities at the interface between the fluids which leads to complex patterns of intrusion of the former into the latter. The complex intrusion pattern results in impurities during the transportation. Hence instabilities need to be removed to ensure smooth transportation of fluids during processing.

Scientists from Raman Research Institute, an autonomous institute of the Department of Science & Technology, Govt. of India, have found that by changing the viscosity of the displacing fluid and the concentration-dependent elasticity of the displaced fluid, the instability can be reduced and the roughness of the interfacial pattern and the efficiency of displacement can be controlled.

In this study, funded jointly by DST SERB India and Raman Research Institute, the researchers used corn starch aqueous suspensions, (a non-Newtonian viscoelastic fluid), and glycerol-water mixtures (a Newtonian fluid) in their experiment. In the first set of experiments, the viscosity ratio between the two fluids (glycerol-water mixtures, the displacing fluid, and corn starch suspension, the displaced fluid) was changed by changing the viscosity of the glycerol water mixture. The viscosity of corn starch suspension was constant in this case while the viscosity of the mixture of glycerol and water was varied by changing the proportion of glycerol in the glycerol-water mixture. In the second set of experiments where the effect of elasticity of corn starch suspension is investigated, the viscosity ratio was kept constant. The elasticity of corn starch suspension was changed thereby changing its concentration, while viscosity ratio between the fluids was kept constant by choosing different concentration of the glycerol-water mixture. The research has been published in the journal ‘Colloids and Surfaces A’.

The suppression of instabilities leads to an efficient displacement of the more viscous/viscoelastic fluid which is useful in transportation of materials in industries such as food processing, oil recovery and sugar refining. The study can also help understand instabilities at the interface between two fluids which is essential in the design and enhancement of processes, like filtration and electrodeposition of metals, as also mixing and demixing of two phases like that of sugar and chocolate which can affect the texture and taste of the chocolate.

Publication link: https://doi.org/10.1016/j.colsurfa.2021.127405

Authors:

Palaka, Rahul Sathyanathb, Sreeram K. Kalpathyb, Ranjini Bandyopadhyaya

a Soft Condensed Matter Group, Raman Research Institute, C. V. Raman Avenue, Sadashivanagar, Bangalore 560 080, INDIA

b Department of Metallurgical and Materials Engineering, Indian Institute of Technology Madras, Chennai 600 036, India

<><><><><>

SNC/RR

Scientists have found a new method to improve the transportation of fluids like chocolates, lotions, sauces by tuning the viscosity and elasticity of fluids during materials processing in the food and personal care products industries.

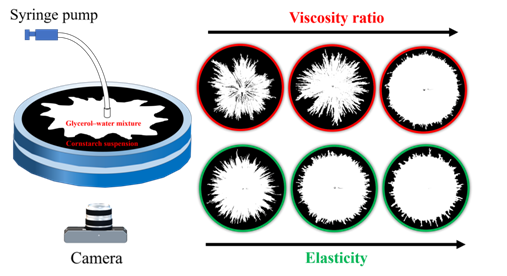

Usually the transport of fluids through pipelines involves displacement of a more viscous fluid by a less viscous one. This creates instabilities at the interface between the fluids which leads to complex patterns of intrusion of the former into the latter. The complex intrusion pattern results in impurities during the transportation. Hence instabilities need to be removed to ensure smooth transportation of fluids during processing.

Scientists from Raman Research Institute, an autonomous institute of the Department of Science & Technology, Govt. of India, have found that by changing the viscosity of the displacing fluid and the concentration-dependent elasticity of the displaced fluid, the instability can be reduced and the roughness of the interfacial pattern and the efficiency of displacement can be controlled.

In this study, funded jointly by DST SERB India and Raman Research Institute, the researchers used corn starch aqueous suspensions, (a non-Newtonian viscoelastic fluid), and glycerol-water mixtures (a Newtonian fluid) in their experiment. In the first set of experiments, the viscosity ratio between the two fluids (glycerol-water mixtures, the displacing fluid, and corn starch suspension, the displaced fluid) was changed by changing the viscosity of the glycerol water mixture. The viscosity of corn starch suspension was constant in this case while the viscosity of the mixture of glycerol and water was varied by changing the proportion of glycerol in the glycerol-water mixture. In the second set of experiments where the effect of elasticity of corn starch suspension is investigated, the viscosity ratio was kept constant. The elasticity of corn starch suspension was changed thereby changing its concentration, while viscosity ratio between the fluids was kept constant by choosing different concentration of the glycerol-water mixture. The research has been published in the journal ‘Colloids and Surfaces A’.

The suppression of instabilities leads to an efficient displacement of the more viscous/viscoelastic fluid which is useful in transportation of materials in industries such as food processing, oil recovery and sugar refining. The study can also help understand instabilities at the interface between two fluids which is essential in the design and enhancement of processes, like filtration and electrodeposition of metals, as also mixing and demixing of two phases like that of sugar and chocolate which can affect the texture and taste of the chocolate.

Publication link: https://doi.org/10.1016/j.colsurfa.2021.127405

Authors:

Palaka, Rahul Sathyanathb, Sreeram K. Kalpathyb, Ranjini Bandyopadhyaya

a Soft Condensed Matter Group, Raman Research Institute, C. V. Raman Avenue, Sadashivanagar, Bangalore 560 080, INDIA

b Department of Metallurgical and Materials Engineering, Indian Institute of Technology Madras, Chennai 600 036, India

<><><><><>

SNC/RR